The Versatility and Benefits of Polyethylene Packaging

In the fast-paced world of manufacturing and shipping, ensuring that your products reach their destination safely and in perfect condition is paramount. One of the most effective solutions to this challenge is polyethylene packaging. Whether you’re shipping fragile electronics or automotive components, polyethylene foam inserts provide a reliable, durable, and eco-friendly way to protect your goods during transit. In this article, we explore the various benefits of polyethylene packaging and how it can be tailored to meet your specific needs.

1. Introduction to Polyethylene Packaging

Polyethylene packaging refers to a versatile and innovative type of protective foam packaging made from polyethylene polymer. This material is used across numerous industries, including electronics, automotive, and healthcare, due to its exceptional shock-absorbing qualities. Polyethylene packaging is especially known for its durability, lightweight nature, and resistance to water, chemicals, and temperature fluctuations.

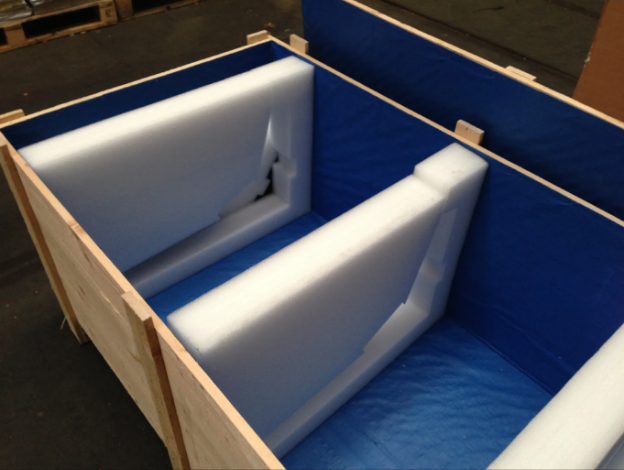

Polyethylene foam is often used as foam inserts inside cartons and boxes to cushion and protect fragile or high-value items during transportation. Its closed-cell structure makes it an excellent choice for absorbing impacts and vibrations, ensuring that your products remain safe even during rough handling.

2. Why Polyethylene Packaging?

Durability and Reusability

Polyethylene packaging is particularly suitable for multi-trip packaging, where the packaging needs to withstand repeated use without degradation. This is a cost-effective solution, especially for industries that require robust and long-lasting packaging materials. Unlike polystyrene, which may degrade over time, polyethylene foam offers long-term durability and reliability, ensuring that your goods arrive safely after many trips.

Superior Shock Absorption

One of the standout features of polyethylene foam is its shock-absorbing capability. The material’s closed-cell structure acts like a series of tiny shock absorbers, effectively spreading out the impact forces and protecting delicate items from potential damage. Whether you’re shipping electronics, medical equipment, or automotive parts, polyethylene foam packaging ensures that your products are cushioned against external forces, reducing the risk of damage during transit.

Water and Chemical Resistance

Polyethylene foam packaging also excels in resisting moisture and chemicals. This makes it the ideal choice for industries that ship products sensitive to environmental factors, such as electronics or automotive parts. The material’s moisture-resistant properties prevent damage from humidity or liquid exposure, while its chemical resistance ensures that it doesn’t break down when exposed to various substances.

Custom Fit and Color Options

Polyethylene foam is highly customizable. It can be easily cut, shaped, and molded to fit the specific dimensions of your product. This ensures that each item is securely packaged and protected. Additionally, polyethylene foam is available in a range of colors, such as black, white, blue, and anti-static pink, making it easier to organize and identify products. Custom-fit foam inserts are particularly useful for tool packs, medical devices, and precision instruments.

3. Applications of Polyethylene Packaging

Polyethylene packaging is used across many industries, each with unique requirements and challenges. Below are some common applications:

Industrial and Factory Transit Packaging

For industries that require protection during factory transit, polyethylene packaging provides a cost-effective solution. It is often used to protect machine parts, electronics, and fragile components during transportation. The ability to reuse the packaging makes it an environmentally friendly option, as it reduces the need for constant repurchasing of new packaging materials.

Tool and Equipment Protection

Polyethylene foam inserts are ideal for protecting tools and equipment. Custom foam inserts can be designed to hold tools securely in place, preventing them from shifting or getting damaged during transport. Additionally, polyethylene foam is available in various colors, making it easy to organize and differentiate between different tools.

E-Commerce and Retail Packaging

With the rise of online shopping, protective packaging is more important than ever. Polyethylene packaging offers a secure way to protect delicate items, such as glassware, electronics, and medical equipment, during shipping. Its lightweight nature reduces shipping costs, while its shock-absorbing properties ensure that products reach customers in perfect condition.

Automotive and Aerospace Applications

Polyethylene foam is widely used in the automotive and aerospace industries to protect car parts, aircraft components, and other precision instruments. The foam’s durability and resistance to environmental factors make it an excellent choice for protecting high-value items that need to withstand long journeys or harsh conditions.

4. The Complete Solution: Custom and Eco-Friendly Packaging

At Advanced Protective Packaging, we understand that every business has unique packaging needs. Our custom packaging solutions ensure that you get the right protection for your products, tailored to your specifications. We work with a wide range of materials, including polyethylene foam, and can design both the outer carton and the internal fitments for a complete packaging solution. This integrated approach helps reduce your sourcing and purchasing time while ensuring that your packaging is both functional and cost-effective.

Read also: Top Tips for a Stress-Free Move

Eco-Friendly Packaging

As sustainability becomes a growing concern for businesses and consumers alike, eco-friendly packaging solutions are gaining traction. Polyethylene foam is a recyclable material, making it an environmentally responsible choice for businesses looking to reduce their carbon footprint. Additionally, many of our packaging solutions are made from sustainable materials, helping you align with environmentally-conscious consumer preferences.

By choosing eco-friendly polyethylene packaging, you not only protect your products but also contribute to a greener future. This can improve your brand image and appeal to eco-conscious consumers who value sustainability in the products they purchase.

5. Benefits of Polyethylene Packaging

Polyethylene foam packaging offers several benefits that make it the ideal choice for businesses seeking reliable and cost-effective packaging solutions:

- Shock Absorption: Ensures fragile products are protected from impact during transit.

- Water and Chemical Resistance: Safeguards products from moisture and environmental contaminants.

- Reusability: Ideal for industries that require packaging to be used multiple times.

- Custom Fit and Color Options: Can be tailored to fit products perfectly, making it easier to organize and identify items.

- Eco-Friendly: Polyethylene foam is recyclable, helping businesses reduce their environmental impact.

6. Conclusion

In conclusion, polyethylene packaging offers a versatile and reliable solution for businesses across various industries. Its excellent shock-absorbing properties, durability, and resistance to moisture and chemicals make it an ideal choice for protecting fragile products during shipping and storage. Furthermore, its customizability and eco-friendly nature ensure that it meets the specific needs of your business while contributing to a sustainable future.

Whether you are looking to protect electronics, automotive parts, or medical devices, polyethylene foam inserts and packaging can provide the protection your products need. By choosing the right packaging solution, you can reduce damage during transit, save on costs, and improve your brand’s reputation for quality and care.